Operating Principles

The Pump Control Unit controls the supply of compressed gas to pneumatic pumps, including Solinst Bladder Pumps and Double Valve Pumps. Drive (pressure) and vent periods are cycled to provide water flow. During pressurization periods water is forced into the sample tubing. The Vent period allows water to re-enter (recharge) the pump. Cycle repetition may be controlled manually or automatically using pre-set pumping rates.

Drive and Vent Cycles

There are two ways users can operatate the Model 464 Electronic Pump Control Unit to obtain the desired sampling rates - preset and customized user flow rate settings.

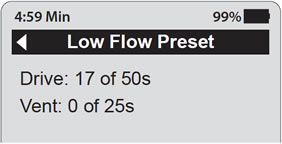

Preset flow rates are built into the Pump Control Unit memory. There is the option of Low, Medium, and High Flow settings.

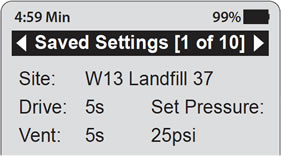

User Flow Rates are customized drive and vent cycles set by the user, then saved in the Control Unit memory for future sampling events. Up to 99 User Flow Rates can be saved to memory.

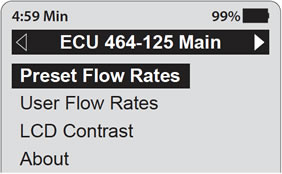

Main Menu

Low Flow Preset Flow Rate

Customized User Flow Rate

Manual Operation

The 464 Electronic Pump Control Unit has the unique ability to operate even when the batteries run out. If the batteries run out, the Solenoid closes automatically. This allows you to use the Manual Control Valve on the Front Panel of the Pump Control Unit. When pushed in the Solenoid opens, which allows a drive cycle; when released, the system is allowed to vent. A manual drive/vent cycle can be performed with just a compressed gas source attached.

Manual operation is also an option on hazardous sites where the batteries are required to be removed for safety reasons.

Obtaining High Quality Samples

The 464 Electronic Pump Control Unit comes in two pressure versions, 125 psi and 250 psi. The higher pressure 250 psi version is ideal to use for deeper applications, or applications where faster purge rates are desired. Both versions are ideal for use with Solinst Bladder Pumps and Double Valve Pumps (see Model 407 Bladder Pump, Model 408 Double Valve Pump and Model 408M Micro Double Valve Pump Data Sheets).

Accessories

464 External Filter

with Draining Valve

The 464 Electronic Pump Control Unit works with the Solinst 12 Volt Compressor. The 12 Volt Compressor is ideal for low flow applications of less than 100 ft (30 m) depths.

The compressor operates using 12 volt DC power source. It operates at up to 125 psi and is equipped with a 2 US gallon (7.6 L) air tank, rated to 175 psi.

When using the 12 Volt Compressor, or any other air compressor with the Electronic Pump Control Unit, it is recommended to use the External Filter. The External Filter connects to the supply line and traps moisture, reducing the risk of it entering the Pump Control Unit.

German

German English

English