To overcome buoyancy, weights are connected to the top of the Deep Sampling Discrete Interval Sampler before lowering. After the first 100 m (300 ft), one 2 kg weight is added for every additional 100 m (300 ft) of submerged depth.

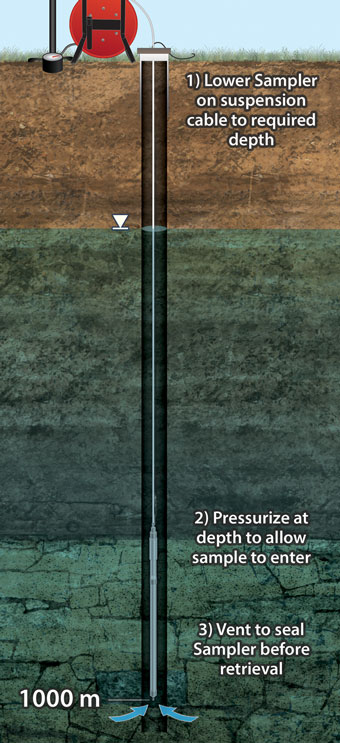

Once the sampler reaches the desired sampling depth, it is pressurized. Using the basic principles of hydraulics, the pressure acts on the top of a piston (larger surface area) inside the sampler, overcoming the hydrostatic pressure acting on the bottom of the piston (smaller surface area) to allow sample water to enter.

As sample water fills the sampler, air from the sampler is vented through holes (covered with a Vyon filter) on the side of the sampler, which are also opened with the applied pressure.

After the sample is collected, the pressure is released, allowing the piston to reseal at the bottom of the sampler. The sealed sampler is then retrieved to surface, maintaining chemical stability of the sample.

At surface, the sample is collected by reapplying pressure to the Discrete Interval Sampler. The flow of the sample is regulated by the amount of pressure applied. The sampler is easily disassembled for decontamination.

| Recommended Operating Pressure and Weights | ||||

|---|---|---|---|---|

| Submerged Depth (feet) | Pressure (psi) | Submerged Depth (meters) | Pressure (kPa) | Number of Weights |

| 160 | 50 | 50 | 345 | 0 |

| 320 | 50 | 100 | 345 | 0 |

| 640 | 50 | 200 | 345 | 1 |

| 960 | 75 | 300 | 520 | 2 |

| 1280 | 100 | 400 | 690 | 3 |

| 1600 | 125 | 500 | 860 | 4 |

| 1920 | 150 | 600 | 1030 | 5 |

| 2250 | 175 | 700 | 1200 | 6 |

| 3250 | 200 | 1000 | 1380 | 9 |

| The 1.66" ø x 2' (42 mm x 610 mm) Deep Sampling DIS has a capacity of 420 ml (14 oz). Sampling at deeper depths may be possible, contact Solinst to determine the suitability of your application. |

||||

German

German English

English