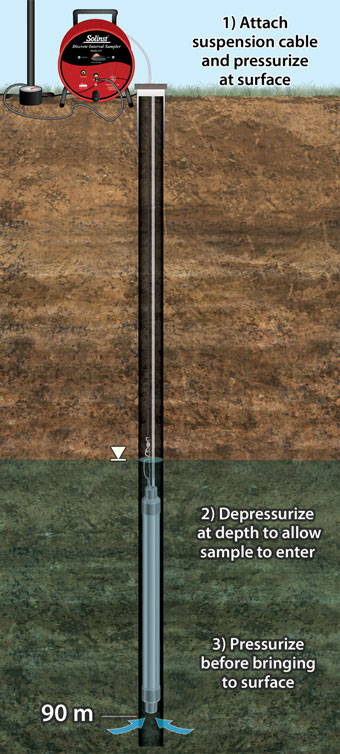

The Discrete Interval Sampler is pressurized before being lowered into the well to prevent water flowing into the sampler. Once the desired depth is reached, the pressure is released and hydrostatic pressure fills the sampler with water directly from the sampling zone. A floating check ball inside the samplers prevents water from entering the tubing, thus avoiding the need to decontaminate the interior of the tubing.

When the sampler is filled, it can be repressurized and raised to the surface. The sample is decanted using the sample release device, which regulates flow and minimizes degassing of the sample. The sampler is easily disassembled for decontamination.

| Recommended Operating Pressure | |||

|---|---|---|---|

| Submerged Depth (feet) | Pressure (psi) | Submerged Depth (meters) | Pressure (kPa) |

| 25 | 20 | 8 | 148 |

| 50 | 30 | 15 | 217 |

| 100 | 50 | 30 | 364 |

| 200 | 95 | 60 | 660 |

| 300 | 140 | 90 | 952 |

| Operating Pressure = (Submerged Depth in feet x 0.43) + 10 psi (Submerged Depth in meters x 9.8) + 70 kPa | |||

| Discrete Interval Sampler Capacity | |||

|---|---|---|---|

| English Units | Metric Units | ||

| Size | Capacity | Size | Capacity |

| 1" x 2' | 6 oz | 25.4 mm x 610 mm | 190 ml |

| 1.66" x 2' | 18 oz | 42 mm x 610 mm | 475 ml |

| 2" x 2' | 27 oz | 50.8 mm x 610 mm | 800 ml |

| 1" x 4' | 12 oz | 25.4 mm x 1220 mm | 365 ml |

| 1.66" x 4' | 32 oz | 42 mm x 1220 mm | 1000 ml |

| 2" x 4' | 61 oz | 50.8 mm x 1220 mm | 1800 ml |

| Other diameters and lengths available, on request. | |||

German

German English

English